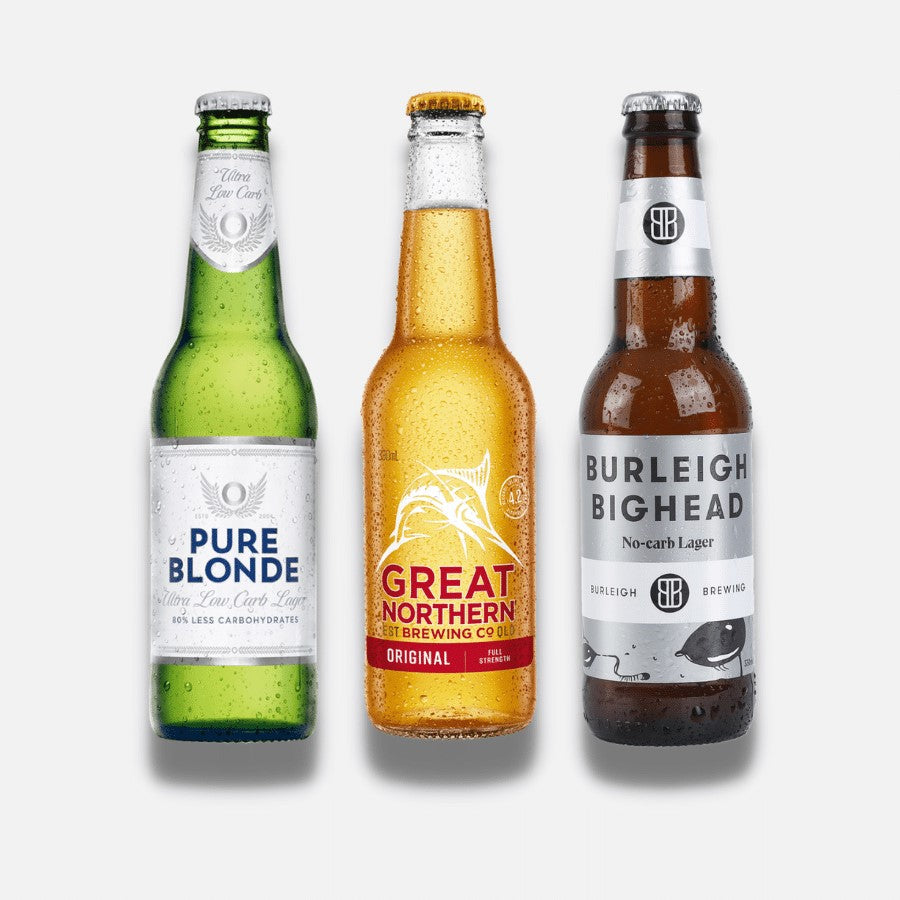

How to Brew a No Lo Carb Beer the easy way with novozymes

Dermott Dowling

No/Lo Carb Beer Guidance Sheet

Attenuation control and light beer production

Novozymes / BeerCo.com.au offer a broad range of attenuation control products to allow brewers to manage attenuation fluctuations, and to create highly attenuated beers, in a simple and cost-effective manner.

Benefits:

- Customised solutions to reach specific attenuation targets and needs

- Manage consumer trends for low calorie and light beer

- Opportunity to reach desired maltose to glucose ratios

- Obtain the desired level of fermentable sugars every time

Products:

Three products can be used alone or in combination to achieve the desired attenuation level and control within the specified production parameters of the individual brewery and brand:

Novozymes Attenuzyme® Pro 25Kg / Benzyme GP 1Kg/5Kg - is a high-performing blend of glucoamylase and pullulanase that makes it possible to hit high attenuation targets in short reaction times, taking advantage of the synergy between these two enzyme activities during the amylopectin and amylose hydrolysis.

Novozymes Attenuzyme® Core 25Kg / Benzyme GA 1Kg/5Kg - is a glucoamylase for producing highly fermentable glucose based worts.

Novozymes Attenuzyme® Clip 25Kg is a pullulanase that accelerates the attenuation, which can be applied for a moderate increase in the attenuation of maltose based wort.

Performance:

The Novozymes / Benzymes range of attenuation enzymes help to break down amylose and amylopectin.

The desired attenuation solution is a choice for the brewery to make. This application sheet focuses on the performance of Attenuzyme® Pro and Novozymes Attenuzyme® Core 25Kg / Benzyme GA 1Kg/5Kg, which are the recommended solutions for highly attenuated beer.

Rates of production of fermentable sugars are dose and time dependent.

Formed fermentable sugars [%] as function of the saccharification time

Fig. 2. Time response curves for Attenuzyme® Core / Benzyme GA and Attenuzyme® Pro on a 50% malt and 50 % corn grist composition at 64ºC, pH 5.4

As a rule of thumb, the RDF (real degree of fermentation) correlates with the amount of fermentable sugars * 0.91.

The amount of fermentable sugars in % of all starch degradation products is plotted as a function of the saccharification time. (The fermentable sugars DP-1, DP-2 plus DP-3 are not corrected for isomaltose and panose). Enzyme dosages in kg/ton grist. As a rule of thumb the RDF corresponds to “Formed fermentable sugars” minus 8-10%.

As shown in figure 2, Attenuzyme® Pro is faster at degrading dextrins into fermentable sugars when compared to Attenuzyme® Core / Benzyme GA due to additional pullulanase activity in Attenuzyme® Pro. The pullulanase works in synergy with malt β-amylase, generating a higher maltose content than Novozymes Attenuzyme® Core / Benzyme GA and shortening saccharification times.

Usage

Dosage response curve for Novozymes Attenuzyme® Core / Benzyme GA

Examples based on recipes with high malt inclusion:

1= Untreated, 2= 1 kg/ton, 3= 2 kg/ton, 4=4 kg/ton, 5=6 kg/ton, 6=8kg/ton, 7=10 kg/ton

Fig. 3. Dosage response (real degree of fermentation [%]) of Novozymes Attenuzyme® Core / Benzyme GA at 64°C after 60 minutes

Grist: 100% malt, saccharification temperature: 63°C, pH 5.3, 60 min.

Starting point: 75% RDF (untreated wort)

Dosage response curve for Attenuzyme® Pro

Fig. 4. Dosage response (real degree of fermentation [%]) of Attenuzyme® Pro at 64°C after 60 minutes

Grist: 100% malt, saccharification temperature: 63°C, pH: 5.3, 60 min.

Starting point: 75% RDF (untreated wort)

Application examples and dosage suggestions

|

Desired Attenuation (%) |

|||||

|

RDF |

ADF |

Option |

Enzymes |

Dosage (Kg/MT) |

Point of Addition |

|

75–80 |

90–95 |

A |

Attenuzyme® Core |

0.35 to 1.0 |

Mashing-in (63°C) |

|

B |

Attenuzyme® Core Attenuzyme® Clip |

0.25 to 0.75 1.2 to 2.4 |

Mashing-in (63°C) |

||

|

C |

Attenuzyme® Pro |

0.3 to 1.0 |

Mashing-in (63°C) |

||

|

80-90 |

95-100 |

D |

Attenuzyme® Core |

2.0 to 6.0 |

Mashing-in or hot wort (63°C) |

|

E |

Attenuzyme® Core Attenuzyme® Clip |

1.5 to 5.0 2.4 to 4.8 |

Mashing-in or hot wort (63°C) |

||

|

F |

Attenuzyme® Pro |

0.25 to 5.0 |

Mashing-in or hot wort (63°C) |

||

Table 1. How to adjust fermentability

Attenuzyme® Core / Benzyme GA and Attenuzyme® Pro are both inactivated during normal wort boiling.

If Attenuzyme® Core / Benzyme GA is used during fermentation the enzyme inactivation during normal pasteurisation temperatures is not possible.

Please contact us at Service@BeerCo.com.au for a dosage suggestion on Attenuzyme® Core / Benzyme GA for cold addition and/or any Technical Support questions.

Please see a link below to a presentation from Dr Aldo Lentini from novozymes at BrewCon23 on Craft Brewing with Enzymes - Nolo and Beyond