Native to human history for 10 thousand years, agave is a great sweetener alternative. Our "Raw Agave Syrup" is made from blue agave hydrolized at 42ºC (107.6 ºF) to preserve the nutrients of agave, which makes it ideal for raw vegan diets.

Application/Industries:

Due to their highly fructose content Organic Raw 100% Blue Agave Syrup is the ideal raw material to obtain Agave distilled products by Industrial fermentative process.

- Alcoholic Beverages

- Bakery

- Cereals

- Chocolate

- Confectionery

- Dairy

- Hygiene

- Non-Alc Beverages

Claims:

- Organic Certified Natural sweetener

- A clean process, no additives or preservatives

- Low glycemic index

- Sugar Cane Free

- Yeast and Gluten Free

- Emphasizes the flavor of the final product

- Greater Maillard reaction

- Ideal for raw vegan and paleo diets

- Kosher Certified

- GMO Free

Recommend Use:

Organic Raw 100% Blue Agave Syrup must be diluted with water until obtain the desired soluble solids (°Brix).

Pack Sizes:

- 5.6 Kg (1 US Gal) HDPE Plastic Bottles

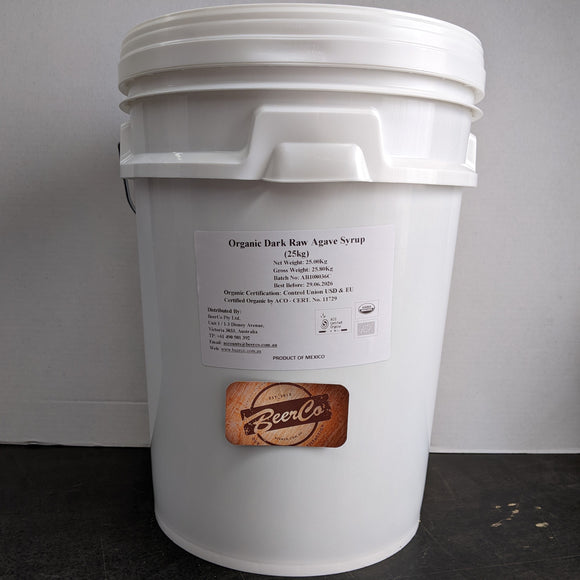

- 25 Kg Pails (SAVE 22% OFF 5.6Kg Price)

- 1380 Kg Industrial Bulk Container (SAVE 33% OFF 25Kg Pail Price)

Technical Specification:

Shelf Life and Storage Requirements:

Without water dilution the Organic 100% Blue Agave syrup shelf life is 3 (THREE) years unopened and without refrigeration. This product must be kept fully closed.

Once opened, the container must be completely consumed.

Raw Organic Agave Syrup must preferably be stored protected from light, at room temperature (25°C/77°F) in a cool dry place.

Product Specifications:

CERTIFICATE OF ANALYSIS

Determination |

Results | Range | Method |

| Brix | 75.7 | 73-76 |

NMX-F-436-SCFI-2011 |

| pH | 4.66 | 4-6 | NOM-003-SAGARPA-2016 |

| HMF | 39.73 | Max. 70 mg/Kg | NOM-003-SAGARPA-2016 |

| Moisture | 24.29 | 23-26% | NOM-003-SAGARPA-2016 |

| Target color (Pfund) | 55 | 46-60 | Colorimeter Hanna |

Chromatographic Profile |

Results | Range | Method |

| Fructose | 88.52 | 85-90% | NOM-003-SAGARPA-2016 |

| Dextrose | 10.99 | 4-14% | NOM-003-SAGARPA-2016 |

| Sucrose | 0.15 | Max 1.3% | NOM-003-SAGARPA-2016 |

| Inulin | 0.06 | 0-6.5% | NOM-003-SAGARPA-2016 |

| Mannitol | 0.14 | 0.006-1.3% | NOM-003-SAGARPA-2016 |

| Other Carbohydrates | 0.13 | Max. 0.13% | NOM-003-SAGARPA-2016 |

Description:

100% Blue Agave Syrup Viscous Liquid, yellow colour, crystalline, free of foreign material, sweet flavour

Microbiological: |

Results | Range |

Method |

| Total bacterial count | <10 UFC/g | Max. 100 UFC/g | Petrifilm |

| Mold | <10 UFC/g | <10 UFC/g | Petrifilm |

| Yeast | <10 UFC/g | <10 UFC/g | Petrifilm |

| Coliforms | Negative | < 3 UFC/g | Petrifilm |

| E. Colli | Negative | < 3 UFC/g | Petrifilm |

| Salmonella | Negative | < 3 UFC/g | Petrifilm |

Certifications, Registers & Third Party-Studies:

The Organic Agave cultivated in Mexico reaches full maturity between 5 to 7 years. Then, the juice from the core or "Piña" is extracted, filtered, heated and concentrated in a syrup with a lighter consistency than honey. It can also be dehydrated to powder for HORECA industries.

Benefits include:

- No Artificial Flavours

- No Preservatives

- Low Calories / Low GIycemic Index

More Information about Agave:

There are over 300 species of Agave. The world comes from the Greek world αγαυή meaning “noble” or “admirable”. Agave grows on thousands of acres at high altitudes, in the red volcanic soils of Central and Western Mexico.

Agave begins as a seed, and once sown, it grows over 8 feet tall and wide. After 5 to 7 years reaches 10 to 15 kg and it’s ready for harvesting.

The harvesting process starts with the cutting of the leaves. The centre of agave is then extracted from the earth and subsequently transported to the factory for further processing.

What’s noble about this plant is their reserve of carbohydrates, as they store fructans (polymers of fructose). Fructose contained in agave requires a simple obtention process.

Premium agave syrup is a natural sweetener produced by thermal hydrolysis of fructans, and its free of food additives, added sugars from other sources and offers a pleasant sweetness.

The Agave syrup is obtained from the agave core. The agave is a millenary plant and its history goes back to ancient times. The agave core is very rich in carbohydrates and the process for converting those in syrup is very simple, it is free of additives and has no artificial ingredients.

BeerCo Best Practice Tips and Advice for Fermentation and Distillation of Agave Syrup for Agave Spirit Production:

- How to Ferment Agave Syrup and Distil Agave Spirit | BeerCo.com.au | Blog | Learn

- How to Make Agave Wash "Mosto Vivo!" the Easy Way with HB Agave Pure | BeerCo.com.au | Blog | Learn